What ist the difference?

WHAT IS THE DIFFERENCE?

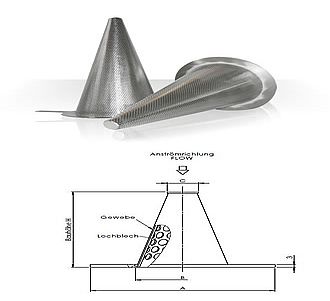

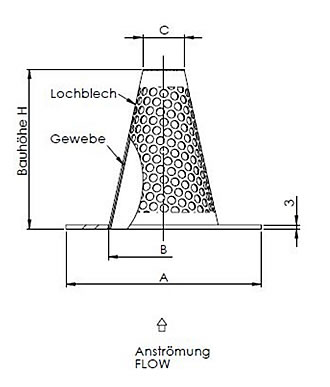

The task is always the same - to remove interfering particles from a medium flowing through a pipeline. Depending on the installation situation, space conditions, pressure conditions, dirt load or other boundary conditions, you can choose between a hat sieve, a strainer or a push-in sieve for the start-up sieve. The flow through a hat sieve is from the tip, i.e. from the outside. The flow through a strainer is from the inside. Due to their design, both variants offer a larger filter surface area than would correspond to the pipe cross-section and thus compensate for the reduction of the open cross-section through the start-up sieve. If there is sufficient capacity you can also choose a push-in sieve, sometimes there is no other option due to the space available.

Start-up sieves consist of a supporting body made of a perforated plate and can be covered with fabric either from the outside - hat sieve - or from the inside - strainer. Double cone screens are an alternative when space is limited, here the overall length is significantly shortened, but the filter area is not reduced.

Select the appropriate product group for further information:

Automatic filters have a wide range of applications for every industry.

Automatic operation or continuous removal of unwanted particles from a liquid means that conventional filter systems such as cartridge and bag filters are no longer necessary.

This significantly reduces operating costs and eliminates all or most of the problems associated with waste treatment.

Cleaning is mainly carried out by up and down or rotating scrapers, driven by an electric or pneumatic motor.

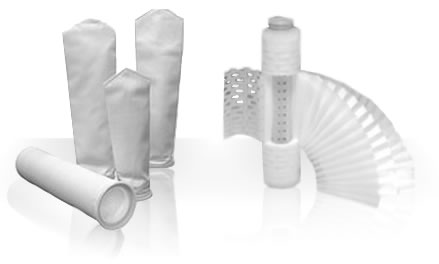

Filtration through filter bags and filter cartridges remains one of the most frequently used filtration techniques.

Our extensive experience together with renowned brands offers the appropriate support for your filtration process. Prefiltration, intermediate or final filtration with filter cartridges made of different media, all common connections and lengths are often available from stock. European certification for use in the food and beverage industry is guaranteed.

Our wide range ensures appropriate replacement or reinstallation in any filtration process. Filter bags or cartridges made of different media, many common connections and dimensions are available. Among the possibilities are, of course, the associated filter enclosures.

Filtration through plates and modules is a common technique in the food industry.

As a member of the Klinger Group, we can look back on more than 50 years of experience in filtration.

A number of innovative alternatives such as modules have been added to our range of quality filter plates. The selection is often determined by user-friendliness and other requirements such as batch process, backwashing or some other technique.

Our hat sieves as intermediate clamping solution for standard flanges (DIN and ANSI) are externally smooth covered with stainless steel wire mesh in different mesh sizes. Perforated plate support body and flange are optionally made of WSt.No. 1.4301 or 1.4571.

We cover all sizes starting from DN25 / 1". Even smaller hat sieves can be found in our special designs.

We also manufacture larger nominal diameters on request.

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Ø Flansch A | PN10 | 106 | 126 | 141 | 161 | 191 | 216 | 271 | 326 | 376 |

| PN16 | 106 | 126 | 141 | 161 | 191 | 216 | 271 | 327 | 382 | |

| PN25 | 106 | 126 | 141 | 167 | 193 | 222 | 282 | 338 | 398 | |

| PN40 | 106 | 126 | 141 | 167 | 193 | 222 | 288 | 350 | 415 | |

| Ø Fuß B | 53 | 68 | 83 | 103 | 128 | 153 | 202 | 253 | 303 | |

| Ø Spitze C | 18 | 18 | 18 | 28 | 28 | 33 | 63 | 63 | 63 | |

| Bauhöhe H | 85 | 119 | 153 | 175 | 232 | 277 | 322 | 435 | 548 | |

Dimensions ANSI

Our standard includes hat sieves from 1" to 14". We can also produce smaller and larger variants for you without any problems.

Our strainers as intermediate clamping solution for standard flanges (DIN and ANSI) are internally smooth covered with stainless steel wire mesh in different mesh sizes.

Perforated plate support body and flange are optionally made of WSt.No. 1.4301 or 1.4571.

We cover all sizes starting from DN25 / 1". Even smaller hat sieves or strainers can be found in our special designs. We also manufacture larger nominal diameters on request.

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Ø Flansch A | PN10 | 106 | 126 | 141 | 161 | 191 | 216 | 271 | 326 | 376 |

| PN16 | 106 | 126 | 141 | 161 | 191 | 216 | 271 | 327 | 382 | |

| PN25 | 106 | 126 | 141 | 167 | 193 | 222 | 282 | 338 | 398 | |

| PN40 | 106 | 126 | 141 | 167 | 193 | 222 | 288 | 350 | 415 | |

| Ø Fuß B | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| Ø Spitze C | 20 | 20 | 30 | 45 | 50 | 65 | 85 | 110 | 130 | |

| Bauhöhe H | 82 | 100 | 115 | 140 | 165 | 190 | 255 | 315 | 375 | |

Our standard includes strainers from 1" to 14". We can also produce smaller and larger variants for you without any problems.