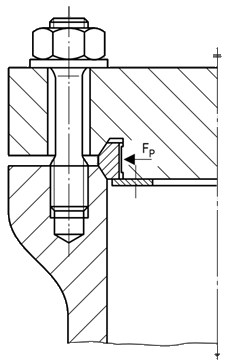

Radially compressed by screw biasing force

Double cone gaskets are radially compressed like a circular spring by the bolt pretensioning force. A pre-tensioning of approximately 1/3 to 1/5 of the test pressure is generally sufficient to achieve the necessary initial seal. So that the gasket does not become overloaded, only a limited amount of clearance should be left between the cover and the gasket.

After pre-tensioning the gasket will initially have contact inside to the cover. With the application of pressure it will then spring back by the compressed amount and if there is sufficient internal pressure will expand elastically, so that it offers reliable sealing in all operating conditions due to its optimal design shape.

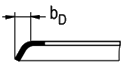

We would be happy to carry out a cost-efficient check for tracking and to determine the measurements of the doublecone gasket as part of our gasket estimate service. The illustration above show the design principle. The measurements of double-cone gaskets are not standardised.

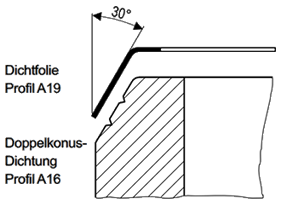

We can currently supply sealing rings up to Ø 3200 mm. The sealing surfaces are conical surfaces with a sloping angle α. A sloping angle of α = 30° is usual, but is not suitable in every case.

There are frequently two or three grooves of a few millimetres wide and a few tenths of a millimetre deep on each conical surface. The grooves fix the enclosed sealing layers into position. The layers provide a better initial sealing behaviour.

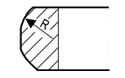

The sealing layers should be no thicker than 1 mm. Aluminium, copper, nickel and silver layers from 0.5 mm to 1 mm in thickness have proven successful. If the sealing layers can no longer be produced in one piece from the semi-finished product, they will be welded. The thickness of the welded joint deviates from the layer thickness by between +0.1 mm to -0.05 mm. Profile AR16 has convex sealing surfaces. The convex model has proven particularly reliable where the strains and curvatures of the component vary greatly, where layers of soft metal are not suitable.

| Profil | Cross-section | Material | k0 (mm) | k1 (mm) | Rz* (µm) |

|---|---|---|---|---|---|

| A16 |  | Steal | - | - | 1,6 - 3,2 |

| AR16 |  | Steal | |||

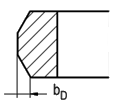

| A19 |  | Cu, Ni, | bD | bD+5 | 3,1 - 6,3 |

| Al, Ag | 6,3 - 12,5 |